-

CORPORATE

CORPORATE

-

WHAT WE DO?

WHAT WE DO?

- OUR PRODUCTS

- OUR SERVICES

- PRODUCTION & RD

- CAREER

- MEDIA

- CONTACT US

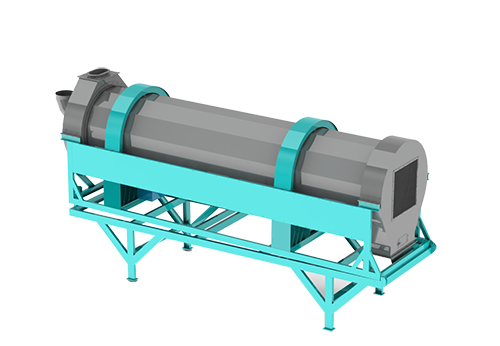

Drum cooler is a piece of equipment that cools products produced by extrusion by releasing their initial heat into the atmosphere. This system, consisting of inlet and outlet hoods and a chassis assembly, operates by being rotated at low speed by a reducer motor. Thanks to the fixed fins on its inner surface, the hot product moves inside the drum and changes position. The fan assembly removes the hot air inside the drum from the atmosphere, allowing the product to cool quickly and effectively.

A cooling drum, inlet and outlet hoods, drum coolers consisting of the chassis assembly, are the equipment that allows the products manufactured by extrusion to cool down by giving the first temperature to the atmosphere. With the rotation of the drum, which is rotated at low speed by a gearmotor, bearing the two ends to the chassis, with fixed fins on its inner surface, the hot product inside it moves and changes position. With the help of the fan assembly connected to the inlet hood, the hot air removed from the drum is released into the atmosphere, thus allowing the product to cool.

Total Area

Closed Area

Blue Collar Staff

White Collar Staff

Feed Production Systems That Feed the Future is a comprehensive approach that combines high quality standards and environmentally friendly production in animal nutrition by offering innovative solutions equipped with modern technologies and focusing on sustainability and efficiency principles.

SUBSCRIBE FOR FAIRS