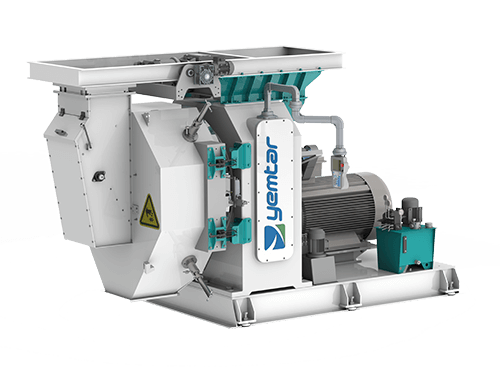

Product; feeding spiral is sent to condenser, double conditioner or pelpeak units. Here, the product annealed with the addition of steam and liquid is spread equally between the rolls and the die and is pressed between 1.5 - 12 mm.

We provide cookies on our site to serve you better. As long as you use our site, you accept our Privacy and Cookie Policy. Clickfor detailed information.