-

CORPORATE

CORPORATE

-

WHAT WE DO?

WHAT WE DO?

- OUR PRODUCTS

- OUR SERVICES

- PRODUCTION & RD

- CAREER

- MEDIA

- CONTACT US

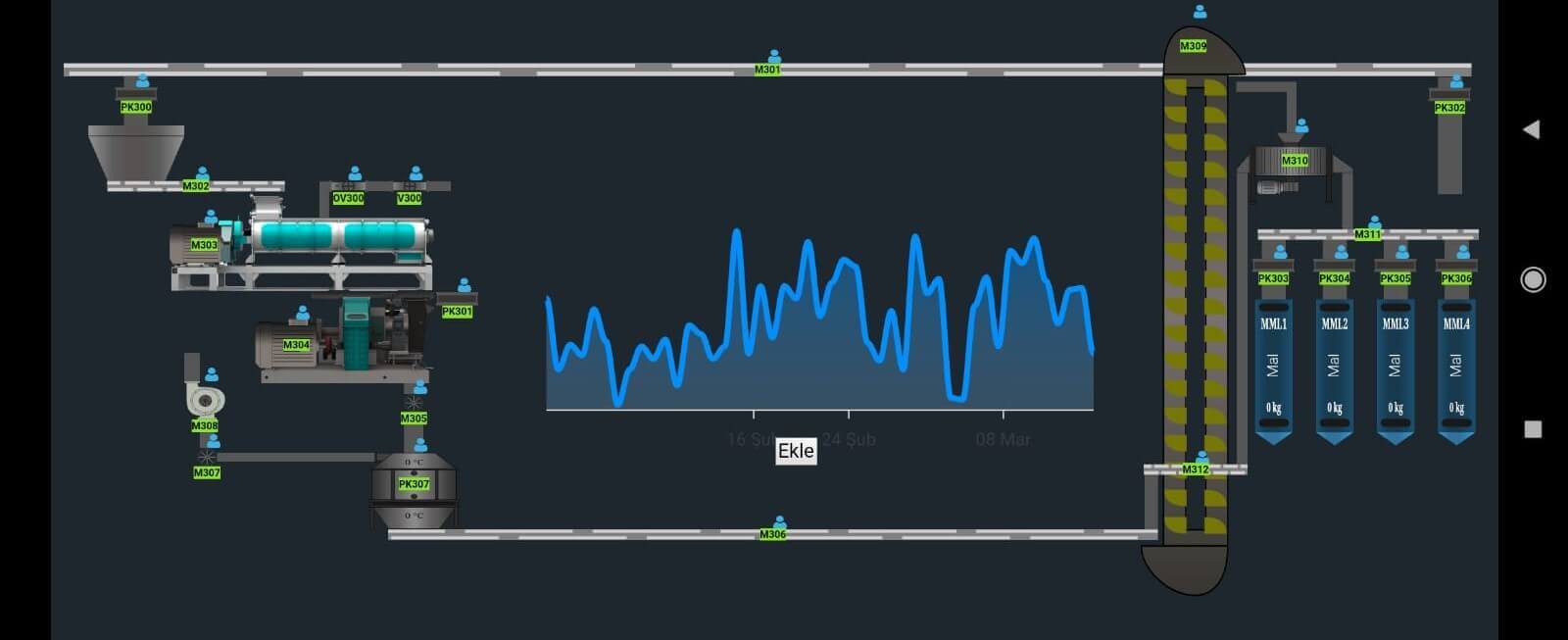

It is a comprehensive solution that provides management of electrical and automation systems in feed production facilities. It integrates all production processes and provides efficient, safe and uninterrupted operation from raw material intake to bagging. Thanks to the central control system, energy management is optimized and operational efficiency is increased.

The system starts with MCC panels

Internal;

MCC Panels

Contactors

Circuit Breakers

Frequency Inverters for Grinding and Pelletizing Unit

Loadcells for Dosing Units

PLC Panels and Controllers

Computerized Control Panel

Field Equipment, Level Sensors, Temperature Sensors etc.

External;

Transformer and Distribution Panels

Cables and Cable Trays

Medium Voltage Line

Field Lighting and Fire Extinguishing System

Telephone Lines

Flowmeter

Control and Automation System Scope;

Raw material intake and distribution

Dosing and Micro Dosing System

Grinding Unit

Mixing Unit

Pelletizing Unit

Bagging Unit

Maintenance and Update over the Internet Electrical Installation Parameters;

Number of Silos and Warehouses: ad.

Number of Carriers: ad.

Number of Electric Motors: ad.

Number of Pneumatic Caps: ad.

Total Power: kw

Required Transformer Power: kva

Total Area

Closed Area

Blue Collar Staff

White Collar Staff

Feed Production Systems That Feed the Future is a comprehensive approach that combines high quality standards and environmentally friendly production in animal nutrition by offering innovative solutions equipped with modern technologies and focusing on sustainability and efficiency principles.

SUBSCRIBE FOR FAIRS