-

CORPORATE

CORPORATE

-

WHAT WE DO?

WHAT WE DO?

- OUR PRODUCTS

- OUR SERVICES

- PRODUCTION & RD

- CAREER

- MEDIA

- CONTACT US

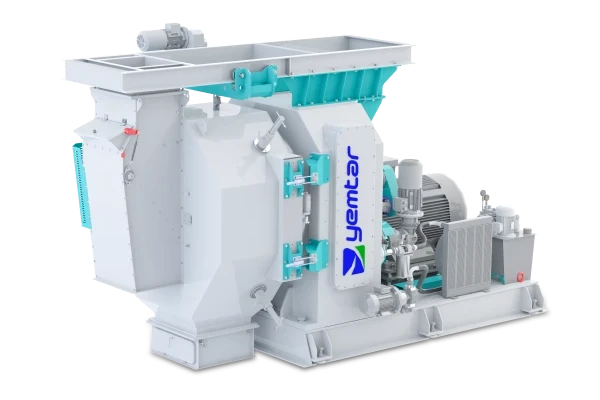

The transmission-driven pellet press performs the pressing process by annealing the product sent to the feed screw, conditioner or Pelpeak units with the addition of steam and liquid. The product is spread evenly between the rollers and discs and pressed into pellets of 1.5-12 mm thickness. With its compact body, it requires less space than belt-pulley presses and provides easy assembly and disassembly thanks to its cover system that can be opened in both directions.

Product; feeding spiral is sent to condenser, double conditioner or pelpeak units. Here, the product annealed with the addition of steam and liquid is spread equally between the rolls and the die and is pressed between 1.5 - 12 mm.

Total Area

Closed Area

Blue Collar Staff

White Collar Staff

Feed Production Systems That Feed the Future is a comprehensive approach that combines high quality standards and environmentally friendly production in animal nutrition by offering innovative solutions equipped with modern technologies and focusing on sustainability and efficiency principles.

SUBSCRIBE FOR FAIRS