-

CORPORATE

CORPORATE

-

WHAT WE DO?

WHAT WE DO?

- OUR PRODUCTS

- OUR SERVICES

- PRODUCTION & RD

- CAREER

- MEDIA

- CONTACT US

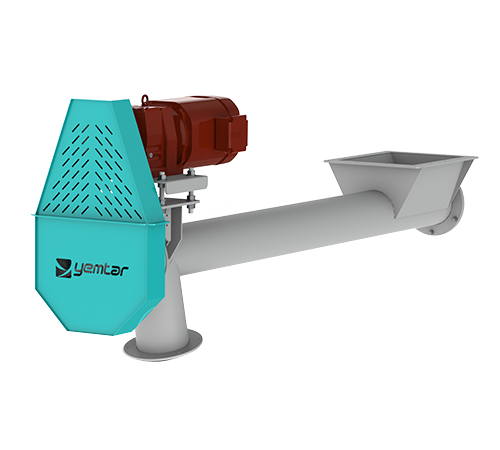

The pipe type helical is a conveyor system designed to transport raw materials and products in industrial facilities such as feed, food, chemistry and fertilizer. The rotor, which consists of helically arranged leaves, rotates on a steel drawn pipe while safely transporting large-grained products horizontally, at an angle or vertically. This system draws attention with its long-term durability and low maintenance requirements. In addition, it minimizes dust formation and provides a clean working environment.

Spiral; It is the carrier that enables the transportation of raw materials and products horizontally, at an angle and vertically in facilities such as feed, food, chemistry and fertilizers. It carries out the transport by rotating the rotor of the leaves, which are helically arranged on the steel draft tube.

Total Area

Closed Area

Blue Collar Staff

White Collar Staff

Feed Production Systems That Feed the Future is a comprehensive approach that combines high quality standards and environmentally friendly production in animal nutrition by offering innovative solutions equipped with modern technologies and focusing on sustainability and efficiency principles.

SUBSCRIBE FOR FAIRS